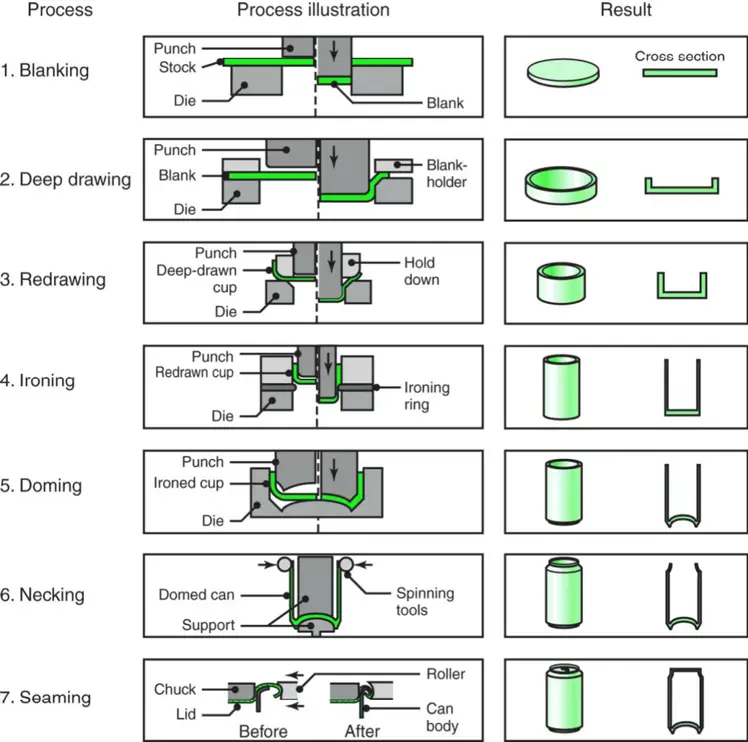

Sheet Metal Fabrication Process

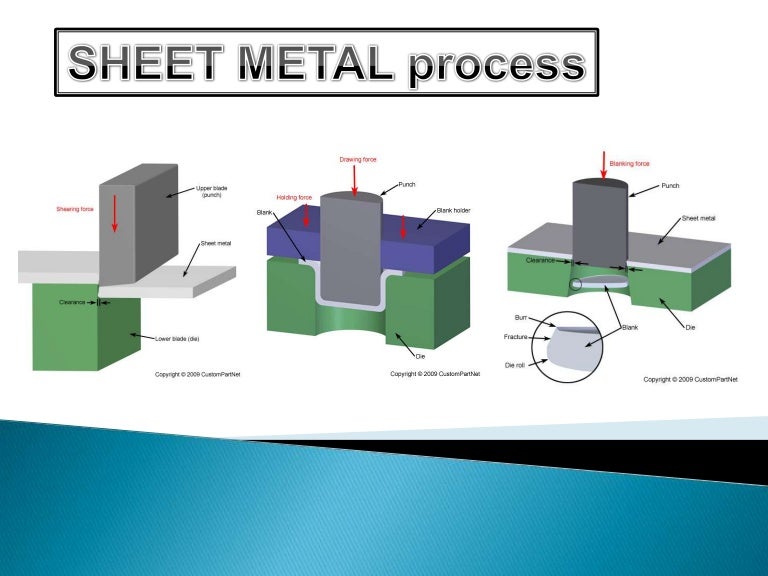

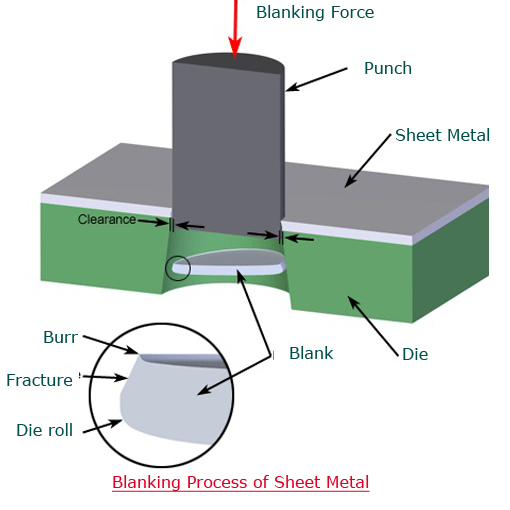

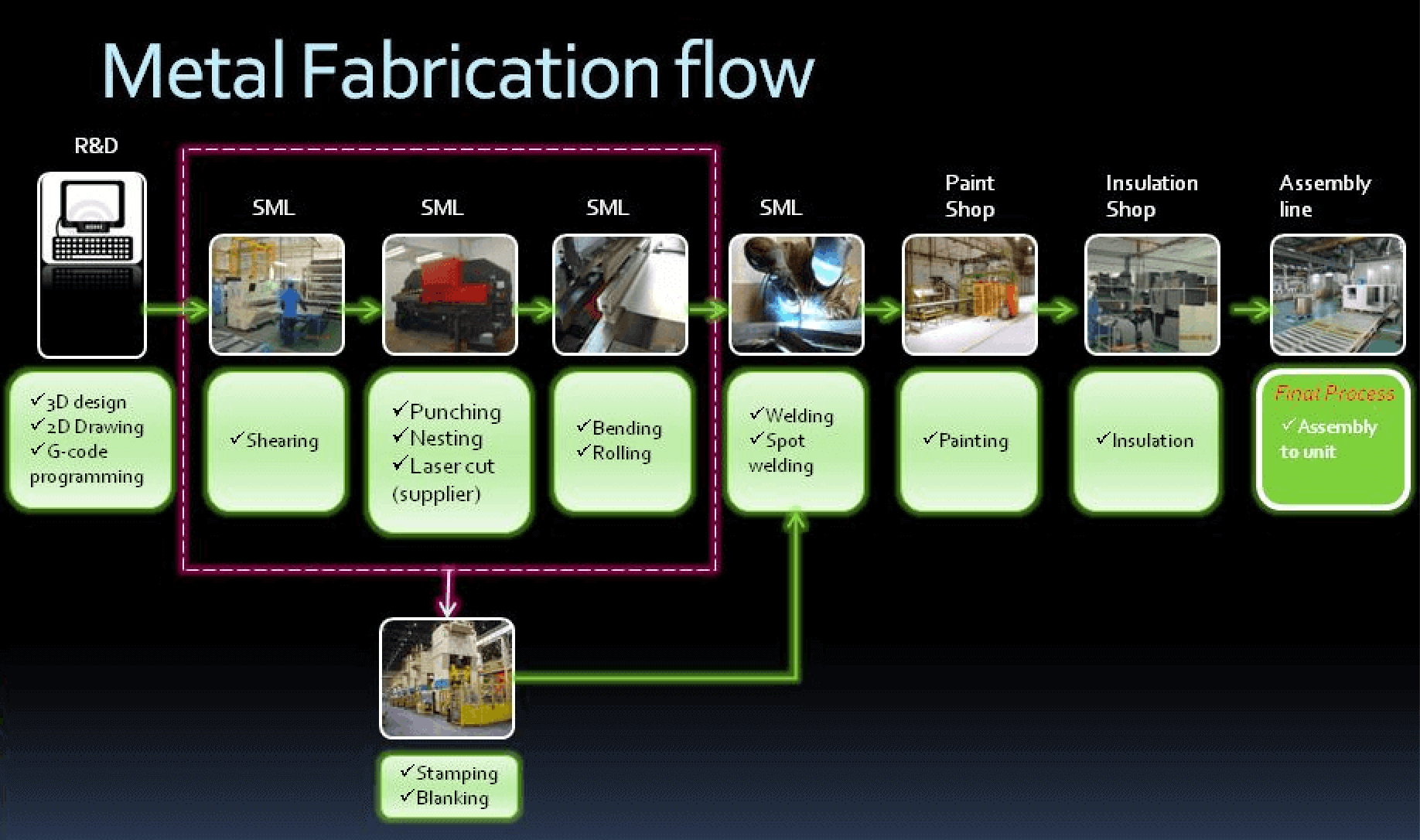

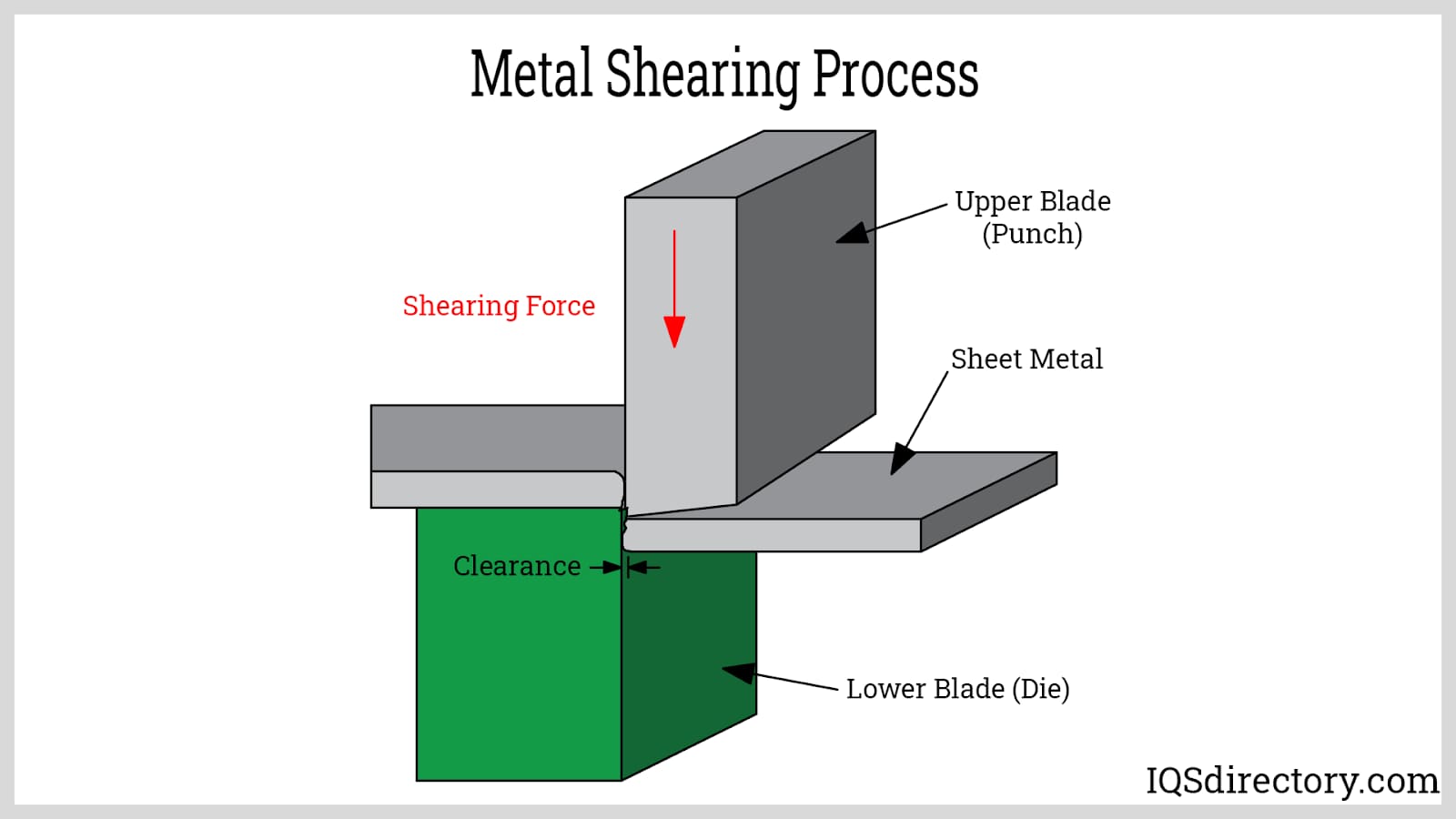

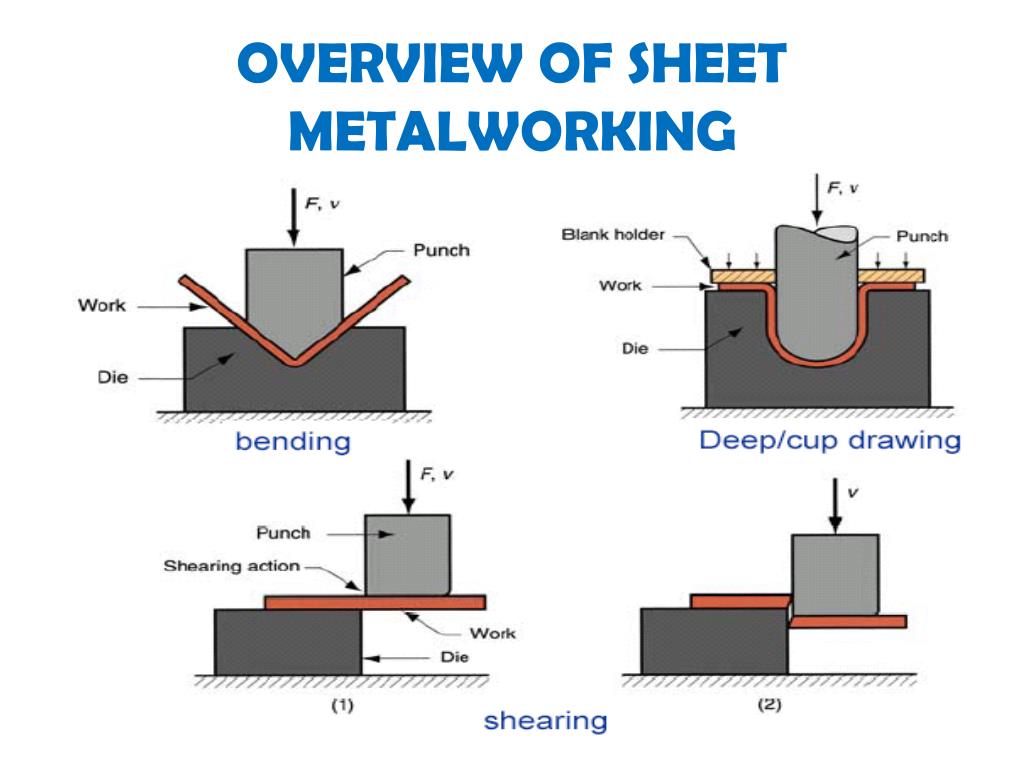

Sheet Metal Fabrication Process - Whether you’re tinkering in automotive, agriculture or beyond,. Sheet metal fabrication isn’t just some factory process, it’s how dreams take shape, one cut and bend at a time. It involves various steps, ensuring the final product meets specific standards and functions. The sheet metal fabrication process is an intricate journey from raw metal to a finished product. The completion of a product usually comprises of. The process of sheet metal fabrication involves turning flat sheets of aluminum or steel into metal structures by cutting, punching, folding, and assembling. Sheet metal fabrication is the process of forming metal sheets to the desired shape using different manufacturing methods. This is accomplished by bending, punching,. The process of producing sheet metal components using metal sheets is known as sheet metal forming or sheet metal fabrication.

This is accomplished by bending, punching,. Sheet metal fabrication is the process of forming metal sheets to the desired shape using different manufacturing methods. Whether you’re tinkering in automotive, agriculture or beyond,. The process of producing sheet metal components using metal sheets is known as sheet metal forming or sheet metal fabrication. The completion of a product usually comprises of. The sheet metal fabrication process is an intricate journey from raw metal to a finished product. Sheet metal fabrication isn’t just some factory process, it’s how dreams take shape, one cut and bend at a time. The process of sheet metal fabrication involves turning flat sheets of aluminum or steel into metal structures by cutting, punching, folding, and assembling. It involves various steps, ensuring the final product meets specific standards and functions.

Sheet metal fabrication is the process of forming metal sheets to the desired shape using different manufacturing methods. Whether you’re tinkering in automotive, agriculture or beyond,. The sheet metal fabrication process is an intricate journey from raw metal to a finished product. The process of producing sheet metal components using metal sheets is known as sheet metal forming or sheet metal fabrication. The completion of a product usually comprises of. This is accomplished by bending, punching,. The process of sheet metal fabrication involves turning flat sheets of aluminum or steel into metal structures by cutting, punching, folding, and assembling. Sheet metal fabrication isn’t just some factory process, it’s how dreams take shape, one cut and bend at a time. It involves various steps, ensuring the final product meets specific standards and functions.

What Is Sheet Metal Working Process at Curtis Coakley blog

The process of sheet metal fabrication involves turning flat sheets of aluminum or steel into metal structures by cutting, punching, folding, and assembling. It involves various steps, ensuring the final product meets specific standards and functions. The sheet metal fabrication process is an intricate journey from raw metal to a finished product. This is accomplished by bending, punching,. Sheet metal.

Types Of Sheet Metal Manufacturing Process at Tillie Burrell blog

The sheet metal fabrication process is an intricate journey from raw metal to a finished product. It involves various steps, ensuring the final product meets specific standards and functions. This is accomplished by bending, punching,. Whether you’re tinkering in automotive, agriculture or beyond,. Sheet metal fabrication is the process of forming metal sheets to the desired shape using different manufacturing.

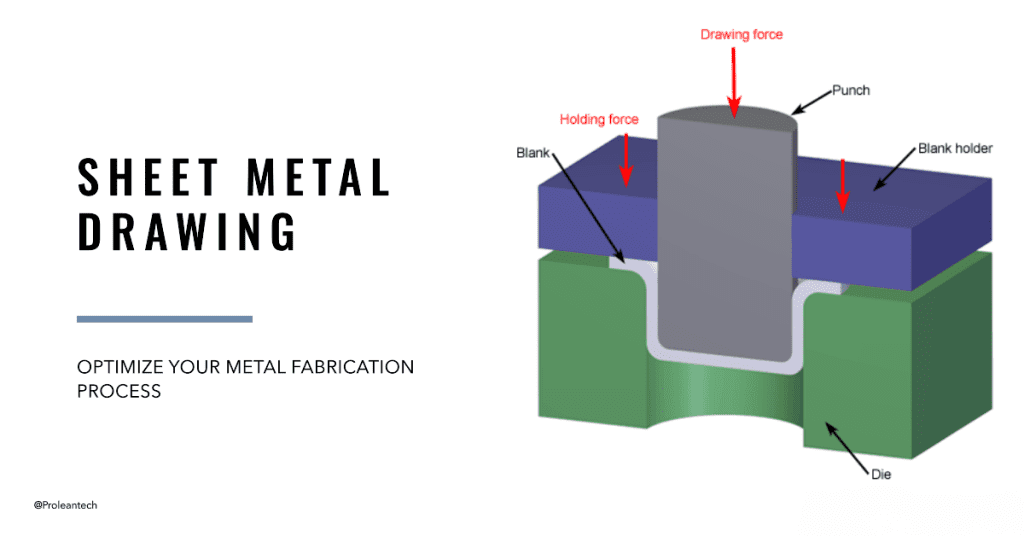

Sheet Metal Drawing Optimize Your Metal Fabrication Process CNC

The sheet metal fabrication process is an intricate journey from raw metal to a finished product. Sheet metal fabrication isn’t just some factory process, it’s how dreams take shape, one cut and bend at a time. This is accomplished by bending, punching,. The process of producing sheet metal components using metal sheets is known as sheet metal forming or sheet.

Sheet Metal Fabrication An Ultimate Guide on Manufacturing Processes

Whether you’re tinkering in automotive, agriculture or beyond,. Sheet metal fabrication is the process of forming metal sheets to the desired shape using different manufacturing methods. This is accomplished by bending, punching,. The completion of a product usually comprises of. The process of sheet metal fabrication involves turning flat sheets of aluminum or steel into metal structures by cutting, punching,.

Sheet Metal Fabrication Process SPS Ideal Solutions Blog

It involves various steps, ensuring the final product meets specific standards and functions. The process of producing sheet metal components using metal sheets is known as sheet metal forming or sheet metal fabrication. Whether you’re tinkering in automotive, agriculture or beyond,. Sheet metal fabrication is the process of forming metal sheets to the desired shape using different manufacturing methods. This.

Sheet Metal Fabrication Process Enclosure Fabrication

The sheet metal fabrication process is an intricate journey from raw metal to a finished product. The process of producing sheet metal components using metal sheets is known as sheet metal forming or sheet metal fabrication. Sheet metal fabrication isn’t just some factory process, it’s how dreams take shape, one cut and bend at a time. The process of sheet.

CostEffective Precision Sheet Metal Fabrication Process

The sheet metal fabrication process is an intricate journey from raw metal to a finished product. The process of producing sheet metal components using metal sheets is known as sheet metal forming or sheet metal fabrication. Sheet metal fabrication is the process of forming metal sheets to the desired shape using different manufacturing methods. The completion of a product usually.

White Paper The Complete Guide To Sheet Metal Fabrication

The process of sheet metal fabrication involves turning flat sheets of aluminum or steel into metal structures by cutting, punching, folding, and assembling. This is accomplished by bending, punching,. It involves various steps, ensuring the final product meets specific standards and functions. Whether you’re tinkering in automotive, agriculture or beyond,. The process of producing sheet metal components using metal sheets.

Processes, Considerations & Advantages of Metal Fabrication

The process of producing sheet metal components using metal sheets is known as sheet metal forming or sheet metal fabrication. Sheet metal fabrication isn’t just some factory process, it’s how dreams take shape, one cut and bend at a time. This is accomplished by bending, punching,. It involves various steps, ensuring the final product meets specific standards and functions. The.

What Is Sheet Metal Working Process at Curtis Coakley blog

The sheet metal fabrication process is an intricate journey from raw metal to a finished product. The process of producing sheet metal components using metal sheets is known as sheet metal forming or sheet metal fabrication. It involves various steps, ensuring the final product meets specific standards and functions. The completion of a product usually comprises of. Sheet metal fabrication.

The Sheet Metal Fabrication Process Is An Intricate Journey From Raw Metal To A Finished Product.

Whether you’re tinkering in automotive, agriculture or beyond,. This is accomplished by bending, punching,. The process of producing sheet metal components using metal sheets is known as sheet metal forming or sheet metal fabrication. Sheet metal fabrication is the process of forming metal sheets to the desired shape using different manufacturing methods.

The Completion Of A Product Usually Comprises Of.

Sheet metal fabrication isn’t just some factory process, it’s how dreams take shape, one cut and bend at a time. The process of sheet metal fabrication involves turning flat sheets of aluminum or steel into metal structures by cutting, punching, folding, and assembling. It involves various steps, ensuring the final product meets specific standards and functions.