Tin Plated Steel Sheet

Tin Plated Steel Sheet - Tin plating, also known as tinning, is a process that involves depositing a layer of tin onto the surface of a substrate, typically steel or another metal. Tinplate consists of sheets of steel coated with a thin layer of tin to impede rusting. Electrolytic tinplate has a maximum thickness of 135 lb. This process is used to provide various. Sheet and tin mill products are differentiated by gauge. The steel substrate provides the necessary strength and formability for specialty fabrication. Explore tin plate and tin coated sheets at randall metals, ideal for packaging and automotive uses, offering superior corrosion resistance and luster. Steel are available in four categories: Electrolytic tinplate—very thin material with a thin coating of tin on steel; It has a certain strength and hardness,.

Sheet and tin mill products are differentiated by gauge. It has a certain strength and hardness,. Electrolytic tinplate has a maximum thickness of 135 lb. Explore tin plate and tin coated sheets at randall metals, ideal for packaging and automotive uses, offering superior corrosion resistance and luster. It is available in either a highly reflective bright surface, or as a. The tin coating acts as a barrier to prevent water and air from corroding or damaging the steel. 1m+ visitors in the past month Tin plating, also known as tinning, is a process that involves depositing a layer of tin onto the surface of a substrate, typically steel or another metal. Tinplate consists of sheets of steel coated with a thin layer of tin to impede rusting. Before the advent of cheap mild steel, the backing metal (known as backplate) was wrought iron.

Tinplate consists of sheets of steel coated with a thin layer of tin to impede rusting. Steel are available in four categories: It is available in either a highly reflective bright surface, or as a. Electrolytic chromium coated steel—very thin material with. Base weight or 0.0149 inch nominal thickness. 1m+ visitors in the past month Tin plating, also known as tinning, is a process that involves depositing a layer of tin onto the surface of a substrate, typically steel or another metal. The tin coating acts as a barrier to prevent water and air from corroding or damaging the steel. Sheet and tin mill products are differentiated by gauge. This process is used to provide various.

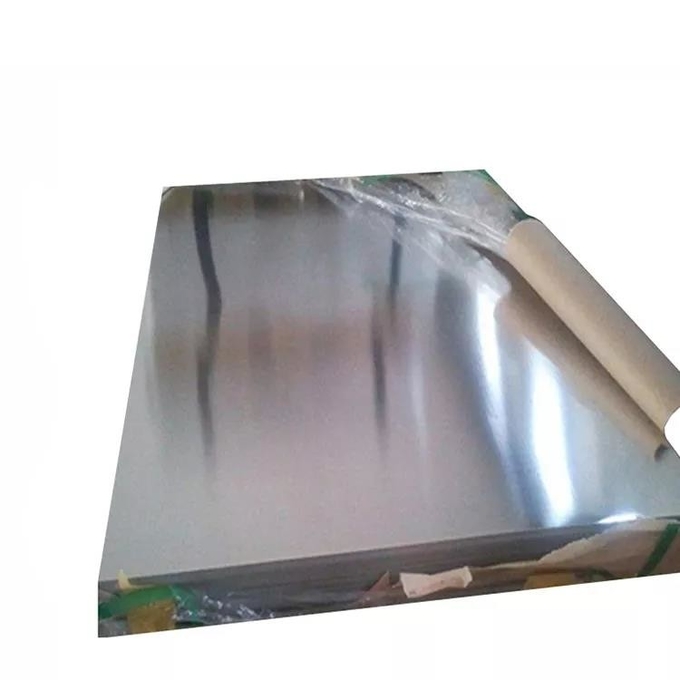

Tin Plate Sheet Cold Rolled Steel Sheet Tinplate Food Container Buy

Electrolytic tinplate—very thin material with a thin coating of tin on steel; Base weight or 0.0149 inch nominal thickness. Before the advent of cheap mild steel, the backing metal (known as backplate) was wrought iron. Steel are available in four categories: Sheet and tin mill products are differentiated by gauge.

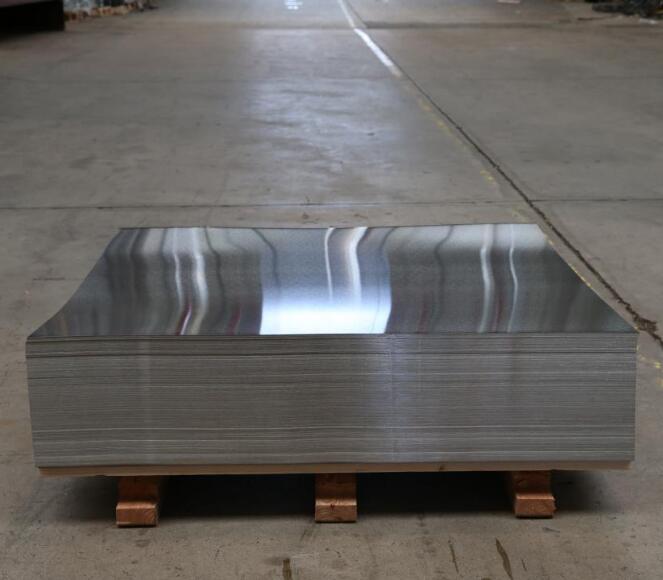

High Quality and low price tinplate steel sheets Sino East

Base weight or 0.0149 inch nominal thickness. 1m+ visitors in the past month Tin plating, also known as tinning, is a process that involves depositing a layer of tin onto the surface of a substrate, typically steel or another metal. Electrolytic tinplate—very thin material with a thin coating of tin on steel; It is available in either a highly reflective.

Tin Plating Steel Sheet Tinpalte for Makeing Food Can Buy Tinplate

This process is used to provide various. Electrolytic tinplate has a maximum thickness of 135 lb. Electrolytic tinplate—very thin material with a thin coating of tin on steel; It is available in either a highly reflective bright surface, or as a. Sheet and tin mill products are differentiated by gauge.

Tin Plate Sheet Cold Rolled Steel Sheet Tinplate Food Container Buy

Explore tin plate and tin coated sheets at randall metals, ideal for packaging and automotive uses, offering superior corrosion resistance and luster. It has a certain strength and hardness,. The steel substrate provides the necessary strength and formability for specialty fabrication. Base weight or 0.0149 inch nominal thickness. The tin coating acts as a barrier to prevent water and air.

Food Grade Matt Finish Tin Plated Steel Sheet Lacquer T3 Tin Coated Sheet

Tinplate consists of sheets of steel coated with a thin layer of tin to impede rusting. Electrolytic tinplate—very thin material with a thin coating of tin on steel; Sheet and tin mill products are differentiated by gauge. It has a certain strength and hardness,. Before the advent of cheap mild steel, the backing metal (known as backplate) was wrought iron.

What is Tin Plating? Aerospace Metals

1m+ visitors in the past month It is available in either a highly reflective bright surface, or as a. Tin plating, also known as tinning, is a process that involves depositing a layer of tin onto the surface of a substrate, typically steel or another metal. Electrolytic chromium coated steel—very thin material with. Before the advent of cheap mild steel,.

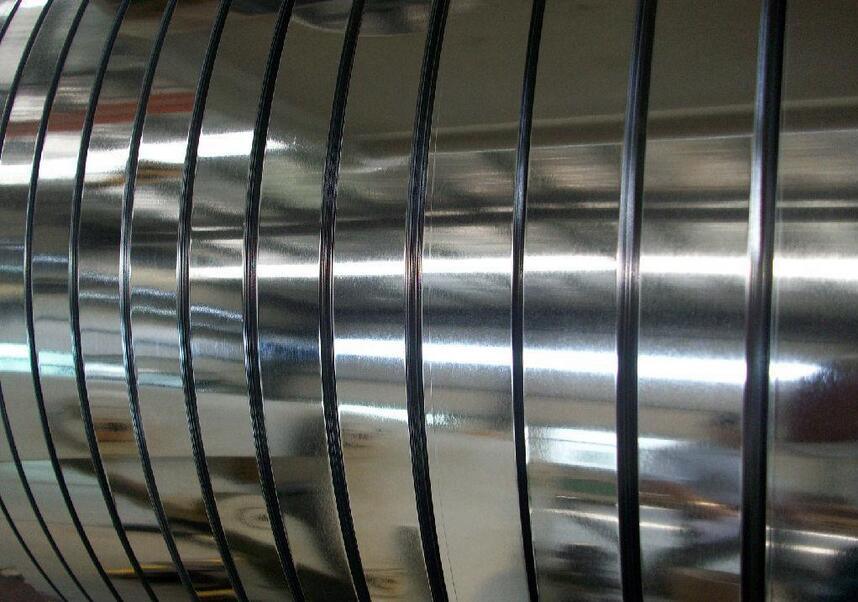

Factory Direct Cold Rolled Tinplate Steel Coil HighQuality Sheet

1m+ visitors in the past month Electrolytic tinplate has a maximum thickness of 135 lb. The tin coating acts as a barrier to prevent water and air from corroding or damaging the steel. Explore tin plate and tin coated sheets at randall metals, ideal for packaging and automotive uses, offering superior corrosion resistance and luster. This process is used to.

Tin Plate Sheet Cold Rolled Steel Sheet Tinplate Food Container Buy

Electrolytic chromium coated steel—very thin material with. Explore tin plate and tin coated sheets at randall metals, ideal for packaging and automotive uses, offering superior corrosion resistance and luster. It has a certain strength and hardness,. This process is used to provide various. Electrolytic tinplate has a maximum thickness of 135 lb.

K&S Metals Tin Sheet, Craft Materials Hobbies

The tin coating acts as a barrier to prevent water and air from corroding or damaging the steel. This process is used to provide various. Steel are available in four categories: Tin plating, also known as tinning, is a process that involves depositing a layer of tin onto the surface of a substrate, typically steel or another metal. The steel.

Tin Plate Food Grade Tin Free Steel Sheet Electrolytic Tinplate Sheet

The tin coating acts as a barrier to prevent water and air from corroding or damaging the steel. Before the advent of cheap mild steel, the backing metal (known as backplate) was wrought iron. Base weight or 0.0149 inch nominal thickness. Electrolytic tinplate has a maximum thickness of 135 lb. It has a certain strength and hardness,.

The Steel Substrate Provides The Necessary Strength And Formability For Specialty Fabrication.

It is available in either a highly reflective bright surface, or as a. Electrolytic chromium coated steel—very thin material with. Tinplate consists of sheets of steel coated with a thin layer of tin to impede rusting. 1m+ visitors in the past month

This Process Is Used To Provide Various.

Explore tin plate and tin coated sheets at randall metals, ideal for packaging and automotive uses, offering superior corrosion resistance and luster. Electrolytic tinplate—very thin material with a thin coating of tin on steel; Sheet and tin mill products are differentiated by gauge. It has a certain strength and hardness,.

Base Weight Or 0.0149 Inch Nominal Thickness.

Steel are available in four categories: Before the advent of cheap mild steel, the backing metal (known as backplate) was wrought iron. Tin plating, also known as tinning, is a process that involves depositing a layer of tin onto the surface of a substrate, typically steel or another metal. The tin coating acts as a barrier to prevent water and air from corroding or damaging the steel.